TCS has managed numerous planned and emergency utility renovation projects. We work with our clients to implement temporary and permanent solutions to return their facilities back to operational status in the most economical and timely manner. We regularly work with clean utilities and are experienced working with client and third-party quality representatives to ensure all necessary documentation is provided. Below are some representative projects in this sector.

Wastewater Treatment Plant Refurbishment, Upgrades & Expansion Project

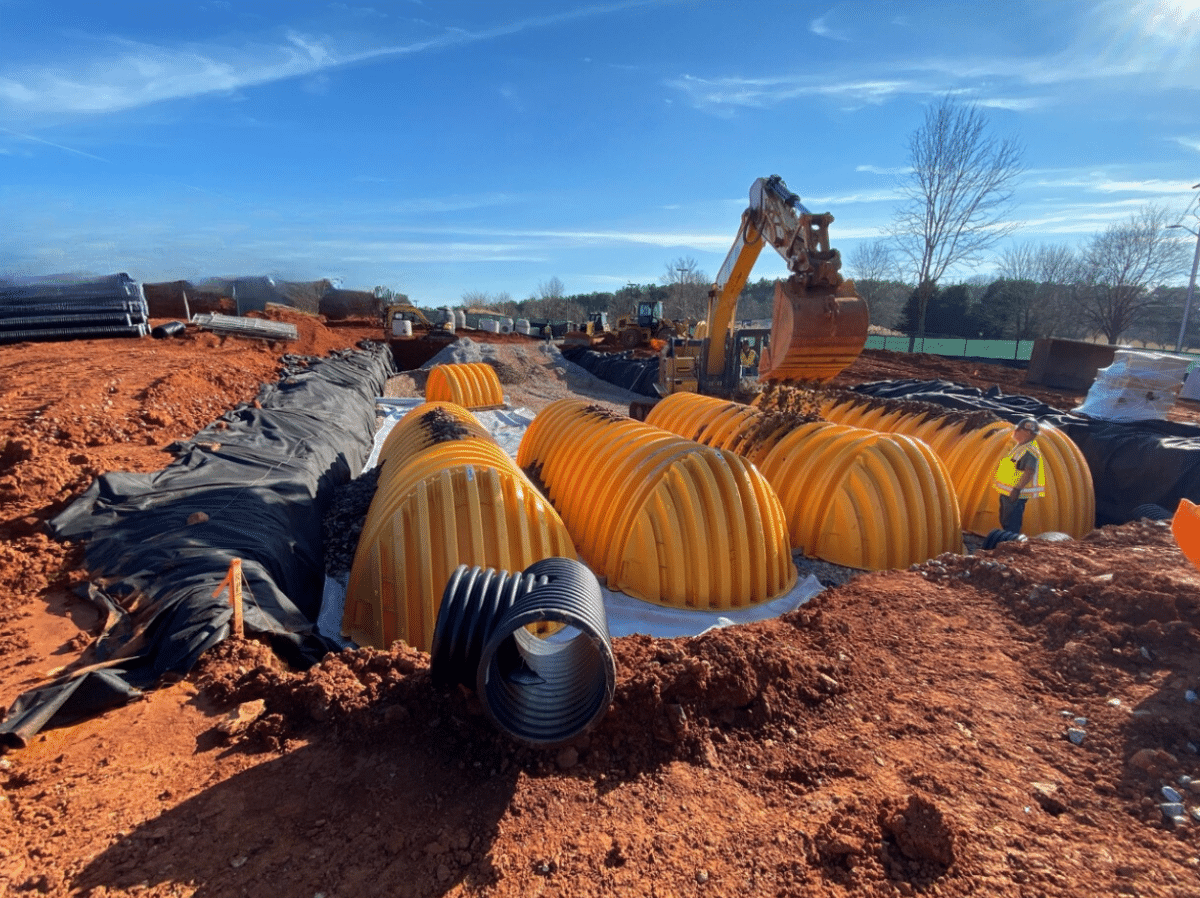

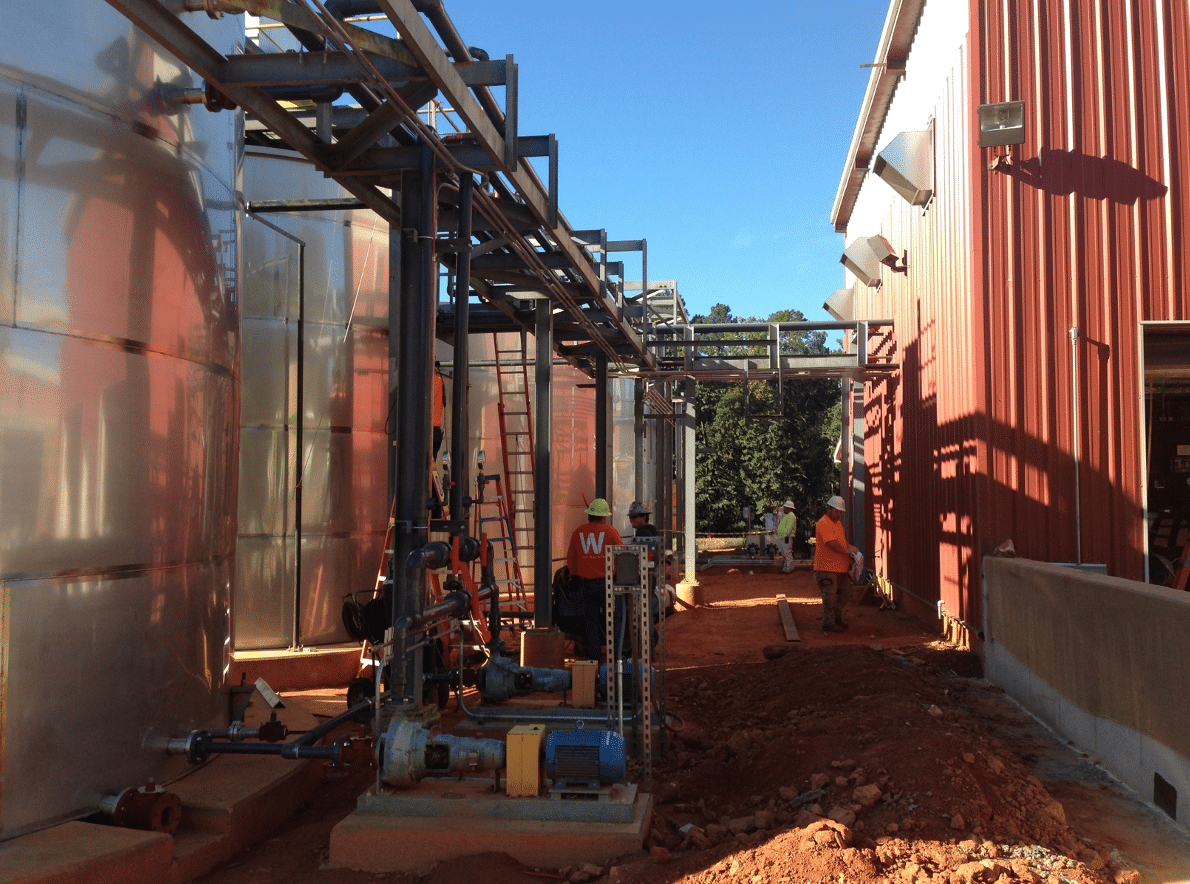

TCS provided Engineering Project Management services to return a site-wide mission critical inoperable Animal WWTP back to full operational status with facility upgrades and an 80% expansion capacity built-in as a fast-track Design/Build project in less than 12 months from the initial catastrophic plant failure, to full operational status / validation. The project consisted of the demolition of existing obsolete process equipment, installation of new welded 316 stainless steel SBR, EQ and Digester tanks, a new larger sludge sterilizer and belt filter press, ultraviolet disinfection system, upgraded boiler and steam heat exchanger, relocation of equipment, piping, valves and sensors for maintenance and accessibility, and the addition of secondary reinforced concrete containment berms and storm water controls. During the plant’s transformation period, a +2.2M gallon holding lagoon was installed along with a temporary waste heat pasteurization processing package for mitigation of off-site waste transport.

Central Services Utility Plant Project

This project was delivered through the Design/Build method, with TCS providing design oversight and Construction Administration services from initial concept, to facility start-up, testing and validation. The project was phase-3, of a 3-phase multi-year Client initiative for increasing their utility generation redundancy and plant optimization. The project included the addition of a new chiller, cooling tower, boiler, custom deaerator, pumps, ancillary piping, facilities distribution sequencing for energy conservation optimization, and integrated building automation controls. These upgrades ensured conformance to external standards for animal facilities regarding mechanical system redundancy as well as mitigating unplanned loss of clinical studies and testing resulting from equipment failures. TCS provided energy utilization optimization, current and projected energy consumption, equipment loss mitigation, and total cost of ownership analysis.

Energy Efficiency & Conservation Projects

TCS has provided engineering, design, and construction project management services on numerous energy efficiency and fuel conversion projects. A sampling of our project list is as follows:

- Campus Wide Energy Conservation Project: This project provided efficiency modifications for utility optimization of the Client’s clinical research campus through fuel conversions from liquid propane fired to natural gas fired, and building systems recommissioning and component re-calibrations. In addition, VFD drives were added and germicidal UV lighting disinfection systems were added to the select AHUs, along with central plant and building wide sequencing controls modifications to optimize system performances. TCS provided energy savings and estimated yearly OPEX reduction analysis to the Client, and worked closely with Siemens Building Automation for implementation of the work. In all, the project provided a favorable net reduction in yearly operating expenses of $208K, with a ROI of 14 months and a net reduction of +520 metric tons per year of CO2 emissions per US EPA Greenhouse gas program guidelines.

- Supply Air Electric to Hot Water Reheat Fuel Conversion Project: Optimization of utility usage in this clinical research facility was achieved through installation of a higher energy efficient reheat system as well as a rebalancing of the facilities’ ventilation air rates from 17.75ACH to 12.5ACH, along with the corresponding water side system adjustments. These optimization modifications were implemented while maintaining ventilation rates required for animal welfare per all regulatory requirements. The project consisted of the installation of a new shell & tube steam to hot water heat exchanger, N+1 circulating hot water pumps, hot water coils, control & bypass valves, BAS modifications integrated into the building automation system and a complete air and water side Test & Balancing certification. This project’s optimization produced a yearly favorable reduction in the Client’s OPEX budget of +$68K per year, providing an ROI just over 4 years. In addition, the conversion resulted in a net reduction of approximately 400 metric tons of CO2 emissions.

- Well Water to Cooling Tower Energy Conservation Project: TCS was contracted to provide the initial engineering analysis for the modifications and upgrades to the Client’s site well water pump and distribution system for energy conservation to feed makeup water to their central plant’s 3 cooling towers and chilled water makeup cooling distribution system. The proposed work involved refurbishment and upgrade of the existing well, pumping and storage system, controls and piping distribution systems and connections to the cooling towers and chilled water systems, including cooling tower zero blow-down technology and recovery system recommendation.

Facility Infrastructure Projects, HSE Safety Upgrades & ME Support

Our team has assisted clients with various projects from infrastructure upgrades to safety projects and integrated PME support for plant shutdown maintenance and repairs. A sampling of our project list is as follows:

- HVAC Upgrades: TCS has managed several HVAC upgrade projects for our clients’ critical manufacturing areas. The upgrades consisted of the refurbishment of several AHUs, ductwork and insulation repairs. At the completion of the projects, TCS managed the rebalance/recertification of the differential pressure (dP) settings, ensuring that they were back in range following the scope of work. Detailed scheduling/coordination with the Client and the contractors was required to minimize operational downtime.

- Mezzanine HSE Safety Upgrades – Phase 1 Project: Design and implementation of upgrades to improve emergency egress, including the installation of emergency and general illumination, exit signage and the relocation of MEP/HVAC utilities that obstructed clear passage throughout the 1.39M Sq. Ft. facility mezzanine catwalk system. The relocated utilities included clean steam, plant steam, deionized water, process chilled water, domestic water and ductwork. TCS worked with the Client’s HSE personnel to prioritize the obstructions and ensured all utilities were operational within the allotted shutdown periods.

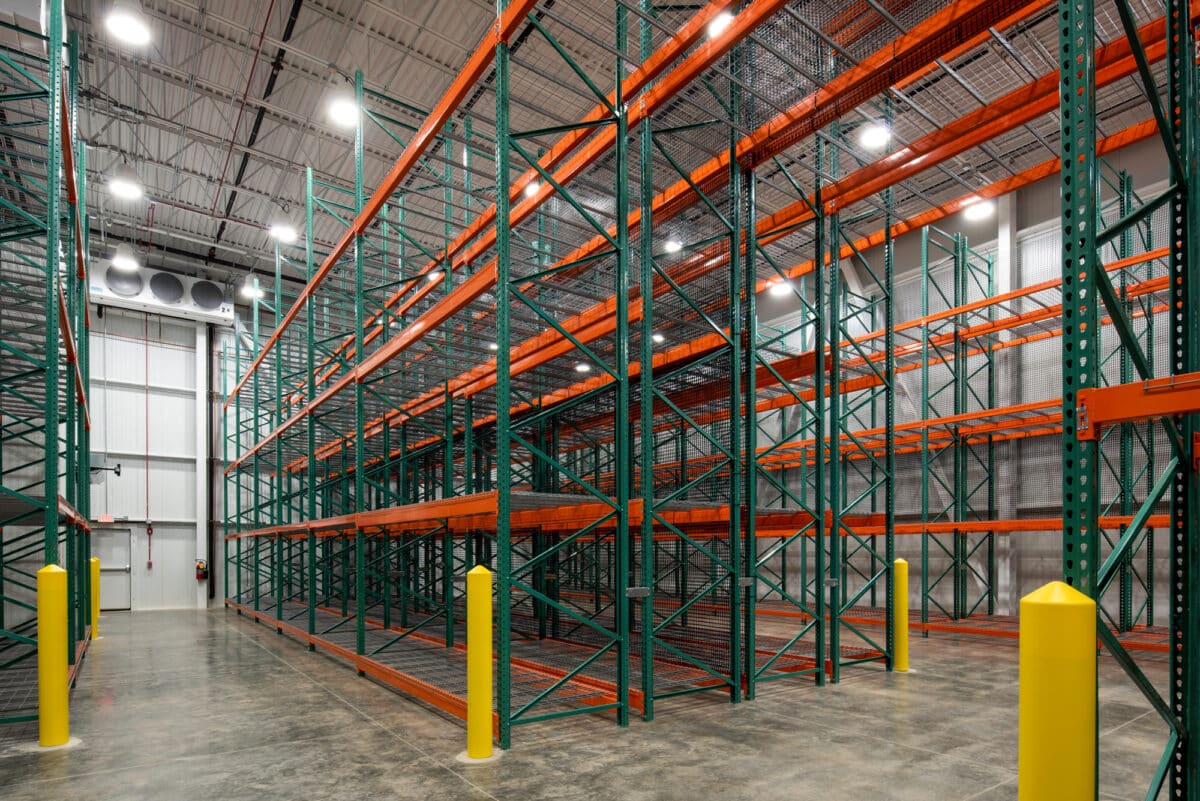

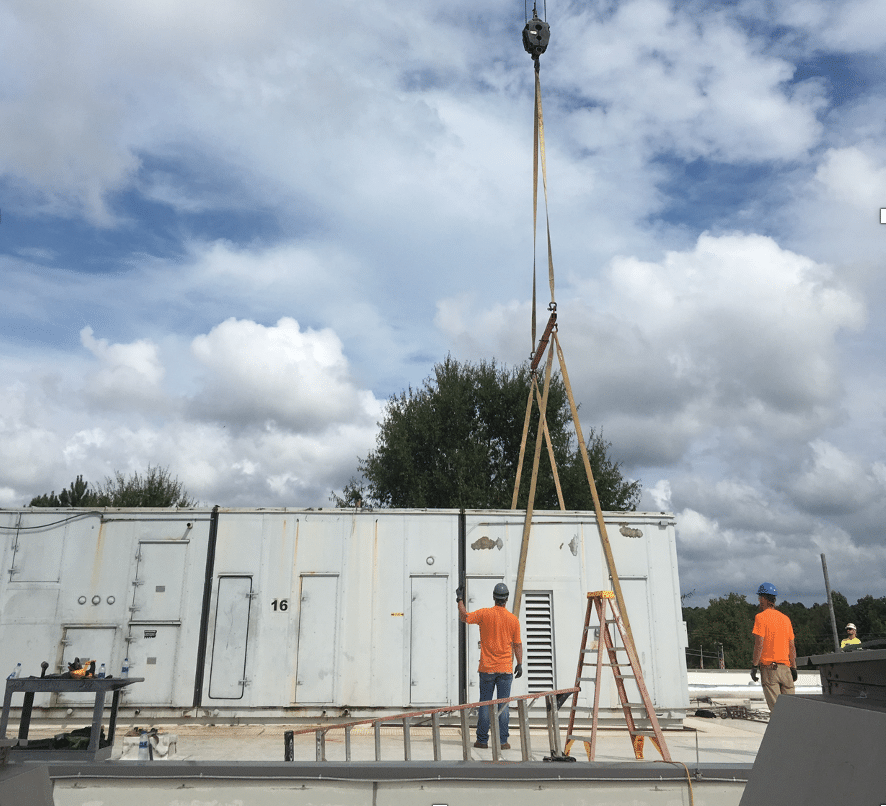

- Misc. Projects: TCS has provided Project Management services for various projects ranging from updating AHU P&IDs, emergency generator installation for critical product storage backup power, RTU/AHU replacements and PME support during yearly plant shutdown maintenance and repair activities. Our team has also been instrumental in supporting our client’s investment upgrades for infrastructure projects where the primary focus was to integrate control monitoring and upgrades, including refrigeration redundancy for their critical research laboratories and product storage coolers.